In the field of refrigeration and air conditioning, compressors play a vital role in thermal management systems. Among the many types of compressors, traditional compressors and electric scroll compressors stand out due to their unique working principles and characteristics. This article will take a deep look at the differences between these two types of compressors and highlight the advantages of electric scroll compressors, especially in applications such as cold chain transportation and high-pressure air conditioning.

Traditional compressor: Rotary refrigeration compressor

Conventional compressors, such as rotary refrigeration compressors, use a rolling rotor structure to compress refrigerant gas. The core component of this system is a helical rotor that operates without a suction valve. This design can extend the suction time and reduce the clearance volume, and is suitable for small refrigeration equipment such as household air conditioners and refrigerators with a power range of 3 to 15 kW.

One of the main advantages of rotary compressors is their compact structure, which can reduce the volume and weight by 40% to 50% compared with other types of compressors. In addition, rotary compressors operate stably and efficiently, which is essential for maintaining optimal temperatures in cold chain transportation. However, rotary compressors have very strict requirements on cleanliness, as any contamination may lead to performance degradation. In addition, the friction between the sliding vanes and the cylinder wall will aggravate speed fluctuations, especially at low speeds, so high processing accuracy is required.

Electric scroll compressors: a modern solution

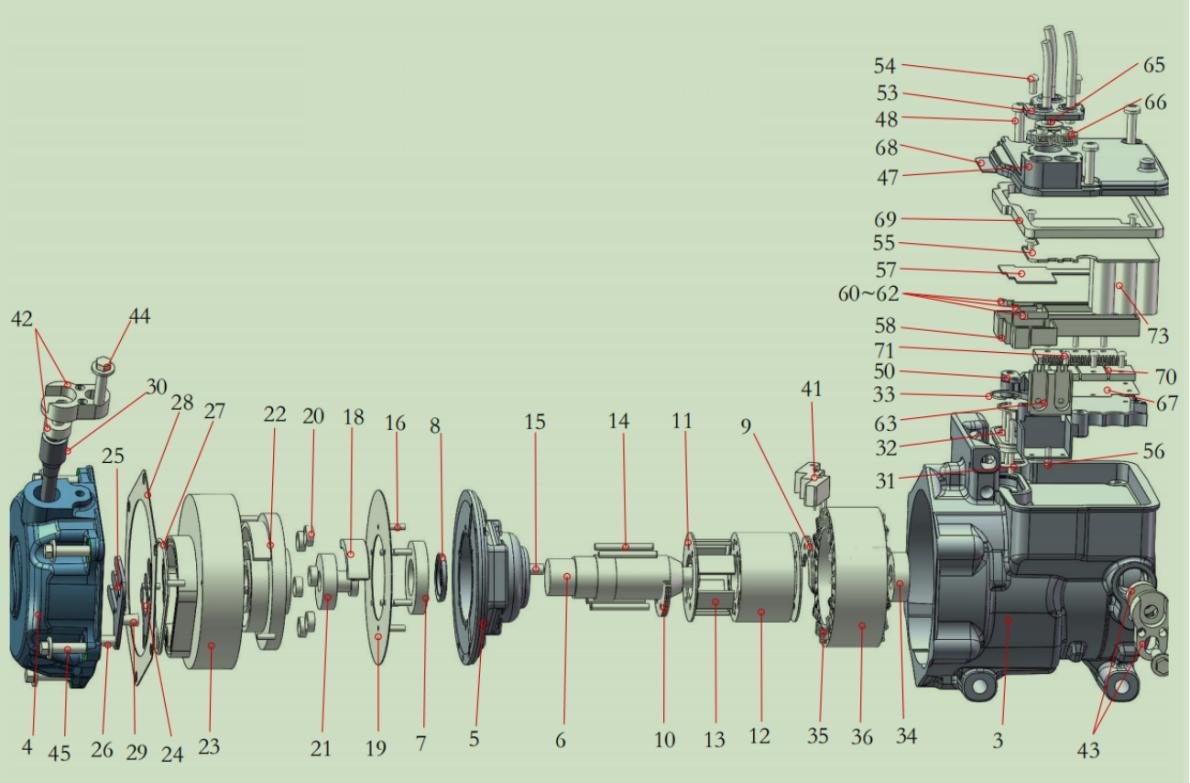

In contrast, electric scroll compressors are popular for their innovative design and efficient operation. This type of compressor consists of a fixed scroll and an orbiting scroll, which mesh with each other at a phase difference of 180° to form a crescent-shaped air cavity. As the orbiting scroll moves, the gas is gradually compressed and finally discharged from the center of the fixed scroll.

One of the most notable features of electric scroll compressors is their volumetric efficiency of up to 98%. This efficiency allows them to deliver up to 20 to 30 horsepower per compressor, making them ideal for air conditioning, heat pumps and refrigeration systems. The scroll compressor’s simple construction, fewer moving parts and lack of a reciprocating mechanism result in lower vibration and noise levels. This is particularly beneficial in residential and commercial environments where noise reduction is important.

In addition, electric scroll compressors are well suited for variable speed operation, enabling precise control of cooling and heating output. This adaptability is critical in modern thermal management systems, especially in high-voltage air conditioning applications where efficiency and performance are critical.

Advantages of Electric Scroll Compressors

When comparing conventional rotary compressors to electric scroll compressors, several advantages of the latter become apparent:

Higher efficiency: Electric scroll compressors have excellent volumetric efficiency, which means better performance and lower energy consumption.

Reduce noise and vibration: There are no reciprocating parts in the scroll compressor, which runs quieter, making it more suitable for residential and commercial environments.

Simplified maintenance: Due to fewer components and simpler design, electric scroll compressors generally require less maintenance than traditional compressors.

Enhanced Control: The ability to operate efficiently at variable speeds enables better thermal management, especially in applications such as cold chain transportation where maintaining a specific temperature range is critical.

In summary, although traditional rotary compressors have a place in the market, electric scroll compressors have become the first choice for modern thermal management systems due to their significant advantages. Their high efficiency, low noise and adaptability to various working conditions make them the leading technology in the field of refrigeration and air conditioning. As the industry continues to develop, the demand for efficient and reliable cooling solutions will only continue to grow, which will further consolidate the position of electric scroll compressors in the field of thermal management in the future.

Post time: Aug-14-2025