Electric scroll compressors have become a cornerstone of modern heating, ventilation, air conditioning (HVAC), and refrigeration systems. Known for their reliability, energy efficiency, and quiet operation. But how exactly do they work? This article explores the mechanics, advantages, and applications of electric scroll compressors.

The Basic Design of an Electric Scroll Compressor

An electric scroll compressor consists of two primary components: Fixed Scroll (Stator): A stationary spiral-shaped element mounted inside the compressor housing.Orbiting Scroll (Rotor): A second spiral that moves in a tight orbital path (without rotating) driven by an electric motor.These two scrolls are precisely machined to interlock with minimal clearance, creating sealed gas pockets that compress refrigerant efficiently.

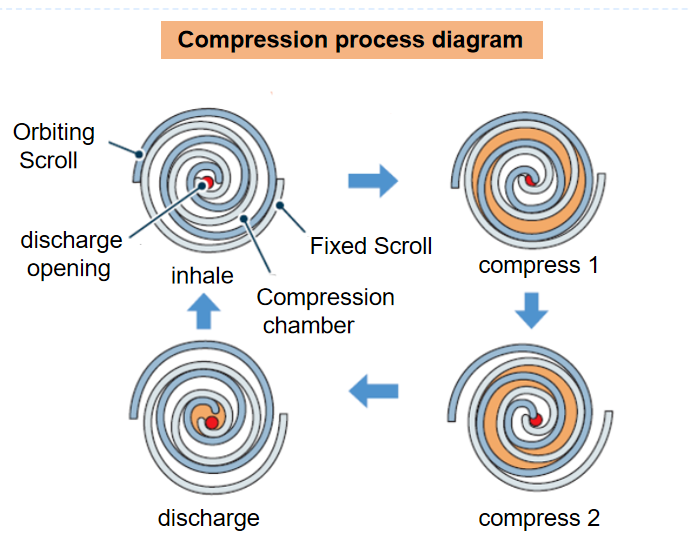

Electric Scroll Compressor Working Principle

First step is Suction Phase.Low-pressure refrigerant gas enters through the compressor’s intake port.The orbiting scroll’s movement draws the gas into the expanding pockets at the outer edges of the scroll set.

The second step is Compression Phase.As the orbiting scroll continues its motion, the gas pockets are pushed toward the center.The volume of each pocket decreases progressively, increasing the refrigerant’s pressure and temperature.

The third step is Discharge Phase.Once the gas reaches the center of the scrolls, it is fully compressed.The high-pressure refrigerant exits through a discharge port, flowing into the condenser for the next stage of the cooling cycle.

Key Advantages of Electric Scroll Compressors

High Energy Efficiency.Fewer moving parts reduce mechanical losses.Continuous compression (as opposed to intermittent piston action) minimizes energy waste; Quiet and Vibration-Free Operation.The smooth orbital motion eliminates the loud “clattering” of piston compressors.

Ideal for noise-sensitive environments like hospitals and residential HVAC systems;Enhanced Durability and Reliability.No valves or reciprocating parts mean less wear and tear.Fewer failure points result in longer service life; Compact and Lightweight.The scroll mechanism allows for a more space-efficient design compared to piston compressors.

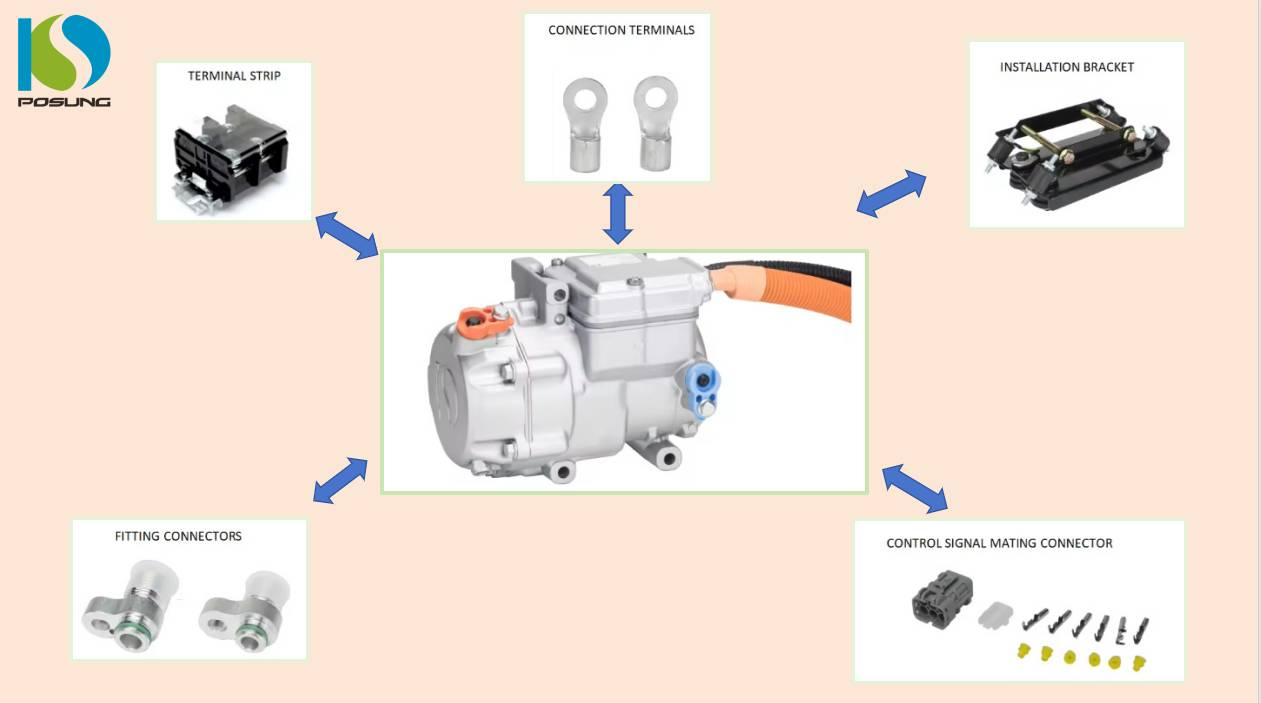

Companies like Posung are leading this trend, replacing traditional coolants with refrigerant direct cooling solutions to optimize the thermal management of electric vehicles.Posung’s product are protected by full intellectual property rights,and also hold multiple patents. According to displacement, there are 10CC, 14CC, 18CC, 24CC, 28CC, 30CC, 34CC ,50CC, and 66CC, 80CC,100CC series. The working range is from 12V to 950V. The compressor can be paired with various refrigerants, such as R134a, R1234yf ,R404a, R407c, R290.

Applications of Electric Scroll Compressors

Due to their efficiency and reliability, electric scroll compressors are widely used in: Electric Vehicle (EV) Heat Pumps: Efficient thermal management for battery and cabin cooling,cold chain transportation.

Future Trends and Innovations

As the world shifts toward electrification and sustainability, electric scroll compressors are evolving with:

Variable-Speed Drives: Adjusting compressor speed for optimal efficiency under varying loads.

Integration with Smart HVAC Systems: AI-driven controls for better energy management.

Use of Eco-Friendly Refrigerants: Compatible with low Global Warming Potential refrigerants like R32 and CO₂ (R744).

Conclusion:Electric scroll compressors represent a significant leap in cooling technology, offering superior efficiency, quiet operation, and long-term reliability. As industries prioritize energy savings and environmental responsibility, these compressors are set to play an even bigger role in the future of thermal management.

Post time: Jun-26-2025